Micropiles: Enhancing Foundation Strength

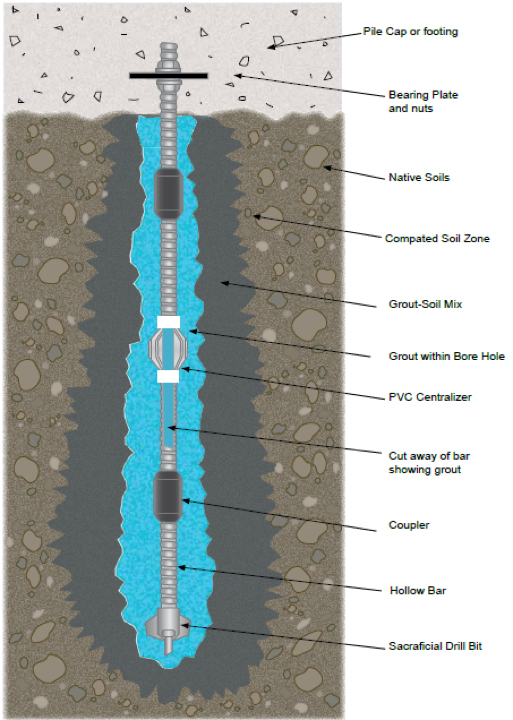

Our micropiling contractors specialize in advanced drilled hollow bar piles and anchors, employing cutting-edge technology for precise installation. Our drilled micropiles, composed of threaded drill rods with sacrificial bits, are advanced to desired depths, creating reinforced cement columns at the core of our foundation solutions. This innovative process of grouting through the center of the drill string and out of the sacrificial bit ensures structural integrity, fortified by the steel drill string. Hollow bar anchors can be used as tie backs, tie downs, rock anchors, soil nails and micro piles.

Our team of micropiling contractors work hard to install versatile and compact equipment that meets the needs of many challenging applications. Contact us today to get a free estimate on our micropiling services!

Skilled Micropile Installation

When it comes to micropile installation, we use various drill bits on hollow bars, offering tailored solutions for different soil conditions and project specifications.

- Carbide Cross-Cut Bits: Highly versatile for a wide range of applications.

- Carbide Button Bits: Specifically designed for micropile installation with hard rock conditions.

- Stepped Clay Bits: Ideal for cohesive clay soil types.

Depending on soil type in your micropile installation, a 3” diameter bit with grout pressure can create a 6” to 8” diameter grout column. The use of hollow bar systems enhances production rates compared to traditional drilled anchors, a particularly advantageous factor in sites with low headroom where there is a risk of bore hole collapse.

Our diverse range of options for your micropile installation ensures optimal performance based on specific project needs and soil conditions. Contact us today to learn more about our micropile installation services!

Request a Free Estimate on Drilled Micropiles Today!

Advantages of Drilled Micropiles

There are many advantages of micro or minipiles, including:

- Hollow bar capacities can reach 150kips each and greater capacities can be reached when used in clusters.

- Small hollow bar drill rigs are capable of operating in confined spaces and even indoors.

- Hollow bar anchors are capable of socketing into bedrock and driving through obstructions.

- Micropiles and their hollow bar anchors offer high corrosion resistance as the steel bar is encased in grout.

- No casing is required to keep the bore hole open and additional capacity is achieved through the skin friction of the grout that is injected into the soil under pressure.

- Minipiles can have casing inserted to keep the grout column intact in karst conditions with large voids.

Explore case studies of our drilled micropiles.

Drilled micropiles are a great asset to your foundation. Get in touch with Keystone Foundation Repair today to see how our micropiling services could benefit your structure!

1-800-822-8880

1-800-822-8880