At Keystone Foundation Repair, we offer sinkhole foundation repair services and have a skilled team of contractors ready to help! For over 20 years, we have been successfully servicing PA and MD areas with top-rated sinkhole repair. We understand the stress that can come with sinkholes, and that is why we work promptly to provide cutting-edge services.

Contact our team to get more information regarding sinkhole repair!

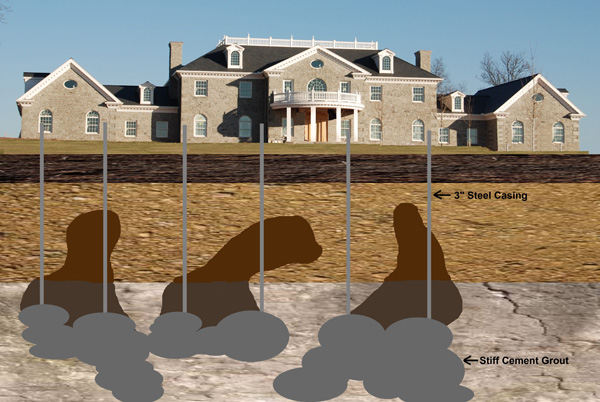

Compaction grouting is commonly used in various construction projects, including foundation stabilization. Our compaction grouting services involve:

During our low mobility grouting, our team will closely monitor the pressure, grout quantity, and surface movement. Then, depending on the design needs, our low mobility grout process will end at max pressure, grout volume, or desired uplift. This method is ideal for non-cohesive soils, especially in sinkholes, and fine-grained soils to enhance bearing capacity and soil behavior.

With our high-quality equipment and industry-leading mentality, you can trust our team to complete superior compaction grouting services on your property. Have additional questions? Learn more about compaction grouting when you give us a call!

Grout casing drill drills into the bedrock

Slump test is performed on grout

Grout is pumped down the casing as it is withdrawn to Certain intervals. Grout pressure & volume are recorded.

With our sinkhole remediation services, you can rest assured that our team will complete all tasks with precision and care. Our sinkhole remediation services do not just focus on taking care of the current problems at hand but preventing future concerns and expenses.

Benefits of our services and sinkhole solutions include:

Interested in learning more? Contact our team today to get started on sinkhole remediation for your property.

With our proven expertise, dedication to quality and advanced techniques and equipment, you can be confident in our sinkhole repair services to restore your property. Throughout the entire process, our team will work hard to complete repairs that preserve the value of your space and look great for many years to come.

Trust us to deliver reliable sinkhole foundation repair solutions that stand the test of time. Get in touch with our team today and claim your free estimate!